By 2026, the definition of supply chain success will have shifted from “surviving disruption” to “orchestrating opportunity.” Staying competitive will require moving beyond reactive resilience (bouncing back) to proactive agility (bouncing forward). Here is how you can navigate the supply chain landscape in 2026, followed by the five specific benefits of SAP Digital Manufacturing (SAP DM) that enable this transformation. The era of treating resilience as merely a defensive shield is over. In 2026, the competitive advantage lies in offensive agility the ability not just to withstand a shock, but to pivot faster than the competition to capture market share when it happens.

As geopolitical fragmentation, strict ESG regulations, and volatile consumer demands converge, manufacturers face a “trilemma”, they must be Agile enough to personalize at scale, Resilient enough to survive global disruptions, and Sustainable enough to meet net-zero mandates.

How do you solve this trilemma without sacrificing profit? The answer lies in the shop floor’s digital transformation. Below, we explore how SAP Digital Manufacturing is helping leaders stay ahead in 2026, highlighting five key benefits that directly address these modern challenges.

The “Glass Factory”: Real-Time Visibility from Shop Floor to Top Floor

In 2026, data silos are the enemy of agility. You cannot pivot a production line if you are waiting for yesterday’s shift report. SAP Digital Manufacturing creates a seamless “Digital Thread.” It integrates the manufacturing execution system (MES) directly with your ERP (like SAP S/4HANA). This means a sales order change in the ERP instantly reflects in the production schedule, and a machine breakdown on the shop floor is immediately visible to supply chain planners. Why it matters in 2026? It eliminates the “latency of decision.” When a raw material shipment is delayed, your system automatically re-optimizes the production queue, ensuring high-priority orders still ship on time.

Predictive Resilience with Embedded AI

Defensive resilience relies on safety stock; offensive resilience relies on prediction. SAP has moved beyond simple monitoring to AI-driven foresight. By leveraging embedded AI and Machine Learning (ML), SAP Digital Manufacturing analyzes historical data and live sensor feeds to predict equipment failures and quality anomalies before they stop the line. Unplanned downtime is a relic of the past. Predictive quality features allow you to adjust machine parameters in real-time to prevent scrap, ensuring that resilience doesn’t come at the cost of efficiency.

Hyper-Agility via Resource Orchestration

The 2026 consumer demands personalization. The days of long, static production runs for a single SKU are fading. Manufacturers need to switch products as easily as a playlist. SAP’s Resource Orchestration (REO) allows for dynamic scheduling of labor and tools. It ensures that the right worker with the right certification is matched with the right machine at the exact moment they are needed. It enables “Lot Size One” efficiency. You can pivot from manufacturing Product A to Product B with minimal changeover friction, allowing you to capture fleeting market trends instantly.

Sustainability as an Operational Metric

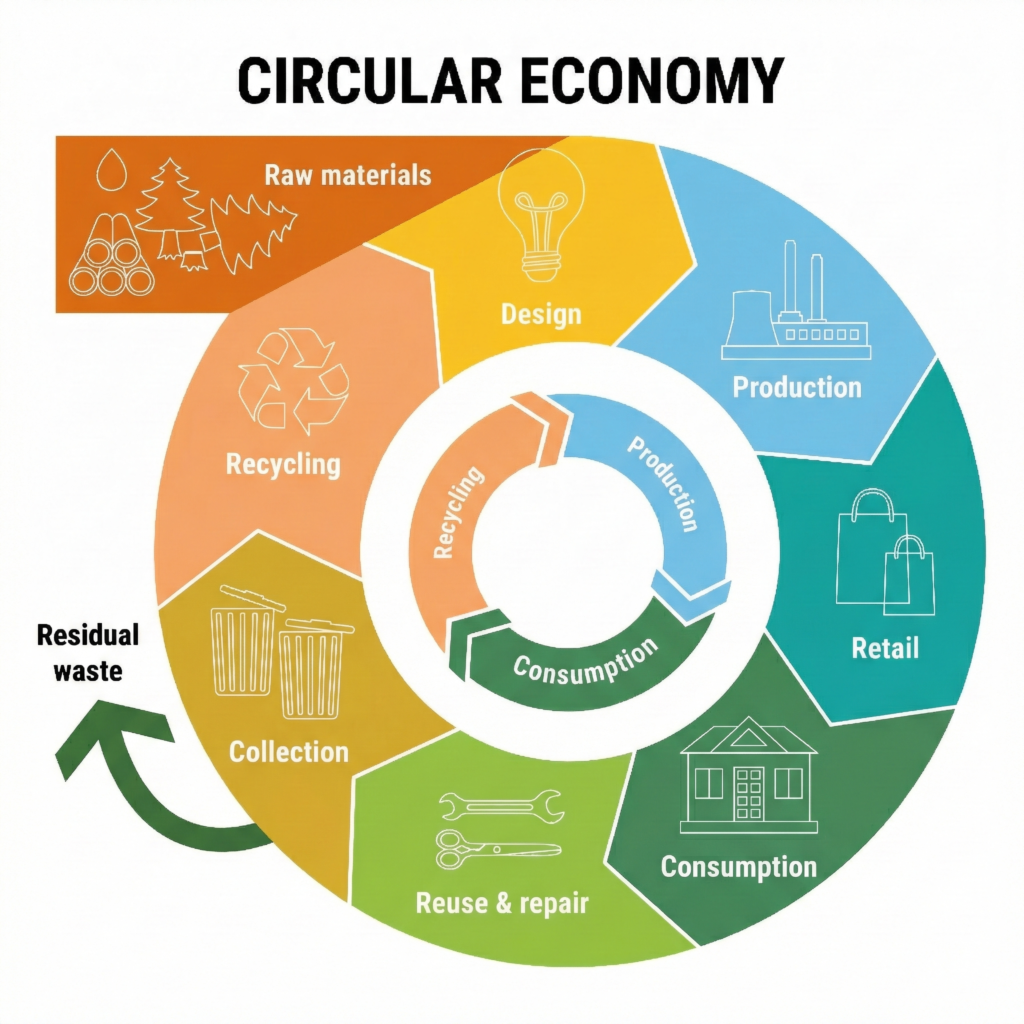

Sustainability is no longer just a corporate report; it is an operational KPI. In 2026, “Green” is synonymous with “Lean.” SAP Digital Manufacturing tracks energy consumption and waste generation at the granular machine and order level. It doesn’t just tell you that you used too much energy; it tells you which specific production run was responsible. You can calculate the true carbon footprint of a single unit. This granular data is essential for complying with 2026’s stricter Digital Product Passport (DPP) regulations and circular economy mandates.

Cloud Scalability for Rapid Expansion

In a fragmented geopolitical world, nearshoring and “friend-shoring” are key strategies. As a cloud-native solution hosted on the SAP Business Technology Platform (BTP), SAP Digital Manufacturing allows for rapid deployment. You can standardize processes in the cloud and roll them out to new plants in weeks, not months, without heavy on-premise IT infrastructure. It matters in 2026, becasue it future proofs your growth. Whether you are acquiring a competitor or opening a nearshore hub, you can integrate them into your digital ecosystem almost immediately.

Future-Proofing Your Operations

The supply chain of 2026 is unforgiving to the slow and opaque.By leveraging SAP Digital Manufacturing you aren’t just installing software; you are building a nervous system for your enterprise one that senses, thinks, and acts in real-time.