When we think of innovation in logistics, our minds usually drift to the tangible: massive autonomous trucks, drones dropping packages on doorsteps, or robotic arms pivoting rapidly in an Amazon fulfillment center. But while those physical robots are revolutionizing how we move goods, a quieter revolution is happening in how we move data.

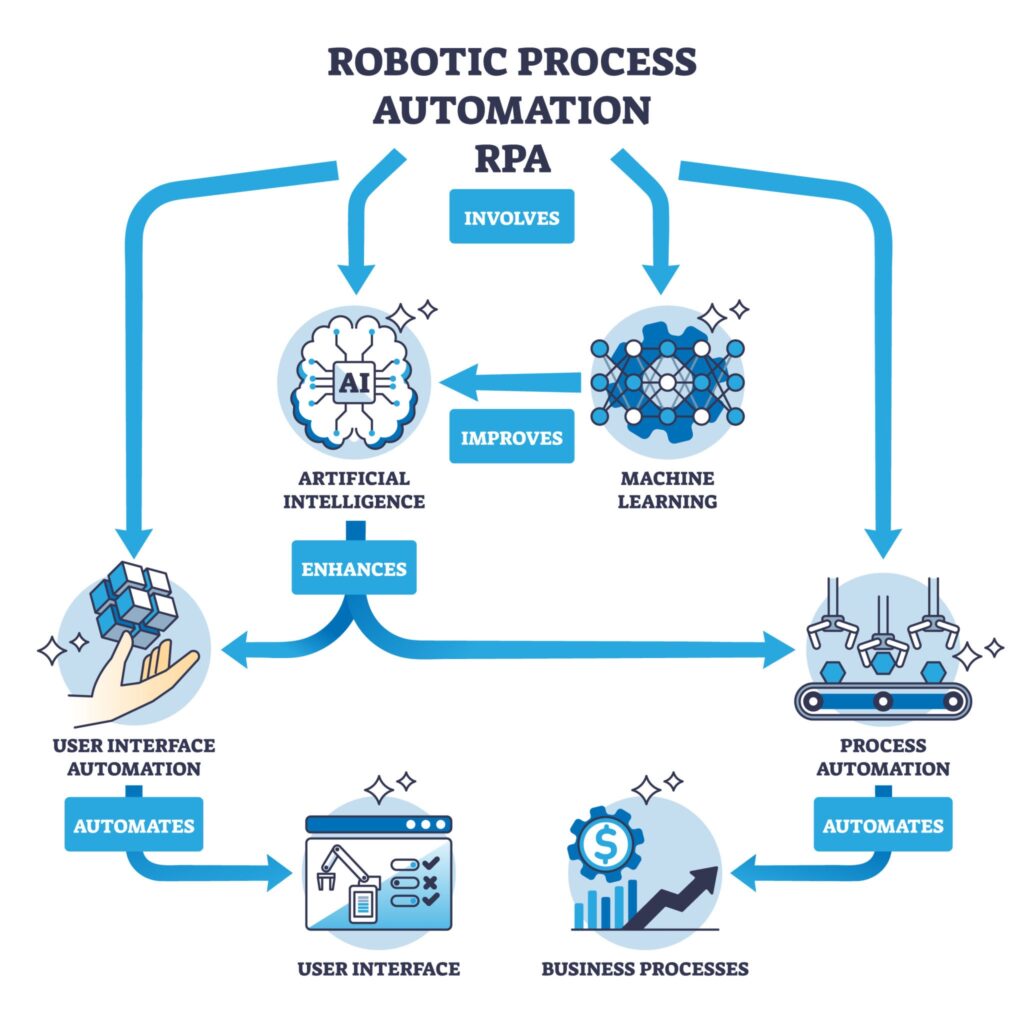

This is the world of Robotic Process Automation (RPA). It is the invisible supply chain that ensures the physical one keeps moving. In an industry defined by tight margins and time sensitivity, RPA has emerged as the critical bridge between chaotic legacy systems and modern efficiency. Robotic Process Automation (RPA) in logistics refers to the use of “software robots” (bots) to handle repetitive, rule-based digital tasks that were previously done by humans.

It is important to clarify a common misconception: RPA is not physical robots moving boxes in a warehouse. It is the invisible software layer that moves data between systems (like Excel, your ERP, and email) to ensure those physical boxes get to the right place.

If the 2026 “Agentic AI” shift I described earlier is the “Brain” (making decisions), RPA is the “Reflex System” (reacting automatically to standard triggers without thinking).

The “Swivel Chair” Problem

To understand why RPA is necessary, you have to look at the current state of a logistics back-office. A logistics coordinator often sits in a “swivel chair” environment. They look at a screen showing a customer email, swivel to a screen showing the Warehouse Management System (WMS), swivel again to a carrier portal (like FedEx or Maersk), and finally swivel to the ERP (Enterprise Resource Planning) software to key in data.

This manual data transfer is slow, soul-crushing for employees, and prone to the “fat-finger” errors that cause shipping delays.

How RPA Works in Logistics

RPA bots act like a digital workforce, RPA is not a physical robot. It is a software bot that mimics human interaction with user interfaces.

If a human can click it, type it, or copy-paste it, an RPA bot can do it only it does so 24/7, at lightning speed, and with 100% accuracy. It acts as a layer of “digital glue” that sits on top of your existing software, connecting systems that don’t naturally talk to each other without requiring expensive custom coding.

Top 3 Battlegrounds for RPA in Logistics

1. The Paperwork Nightmare: Invoice & BOL Processing

Logistics runs on paper digital or otherwise. Bills of Lading (BOL), Proof of Delivery (POD), and carrier invoices flood into inboxes daily.

- The Old Way: A human opens an email attachment, reads the PDF invoice, opens the accounting software, manually types in the invoice number and amount, and checks if it matches the Purchase Order.

- The RPA Way: A bot monitors a specific email folder. When an invoice arrives, it uses OCR (Optical Character Recognition) to “read” the PDF. It logs into the accounting system, matches the data against the PO, and if everything aligns, schedules the payment. Humans are only alerted if there is a discrepancy.

2. The “Where is My Stuff?” Loop: Shipment Tracking

Visibility is the currency of modern logistics. Customers demand real-time updates, but carrier data is often siloed on external websites.

- The Old Way: Staff members spend hours manually checking carrier websites to update the internal dashboard or answer customer calls.

- The RPA Way: Bots are deployed to “scrape” carrier portals at set intervals (e.g., every 15 minutes). They extract the latest status, location, and ETA, and automatically update the company’s internal TMS (Transportation Management System). If a delay is detected, the bot automatically triggers an email to the customer.

3. Order Entry and Inventory Sync

Speed is critical when an order comes in.

- The Old Way: An order comes in via a messy spreadsheet from a client. A data entry clerk spends the morning re-typing that data into the ERP.

- The RPA Way: The bot parses the spreadsheet, validates that the SKUs exist in the catalog, checks stock levels in the WMS, creates the order in the ERP, and sends a pick-ticket to the warehouse floor all in under 30 seconds.

The Critical Distinction: RPA vs. Robotics

It is vital for industry leaders not to confuse these terms.

- Physical Robotics (e.g., Autonomous Mobile Robots) move atoms. They lift pallets and sort packages.

- RPA moves bits. It sorts data and processes logic.

You can have the most advanced physical robots in your warehouse, but if your data is stuck in a manual queue in the finance department, your supply chain is still broken.

The Road Ahead: From Automation to Agency

As we look toward the technological shifts expected in 2026, RPA is evolving. We are moving from “Static RPA” (bots that follow strict rules) to “Intelligent Automation” (bots paired with AI).

In the near future, RPA will provide the “arms and legs” for AI “brains.” An AI model might decide which shipping route is most cost-effective based on global weather patterns, and then command an RPA bot to execute the booking.

For logistics companies, the message is clear: The physical robots get the glory, but the software robots get paid. Implementing RPA is no longer just an IT project; it is a survival strategy for the modern supply chain.

Do you have any questions about Bolders Consulting Group’s services? Or, are you looking for more information regarding our solution development services? Contact Bolders today to learn how we can help transform your business with our technology!